SHARPENING

A quality knife should ALWAYS be regularly sharpened. Watch a professional using cutting or slicing instruments. They routinely sharpen their blades as a matter of course. This can be achieved by using a whetstone or a sharpening steel.

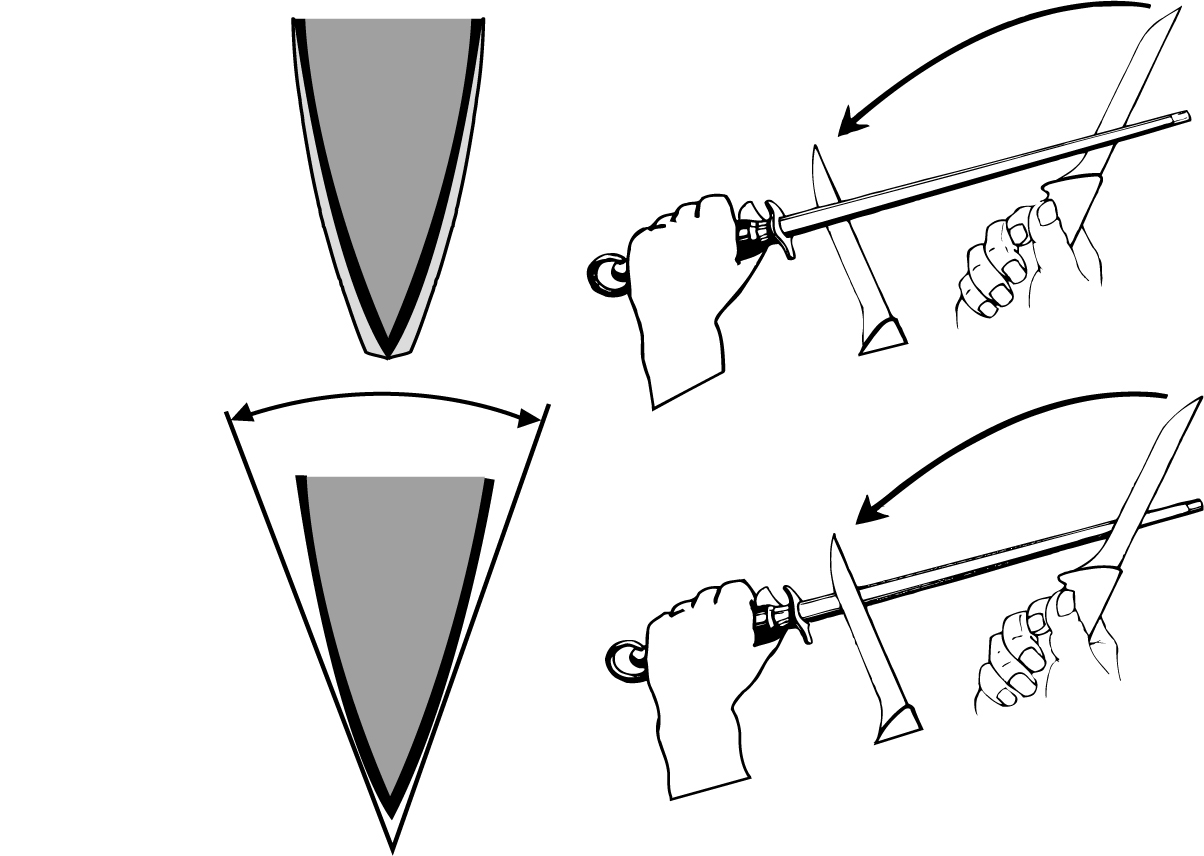

Slide the full lenght of the knife blade along to the full length of the sharpening steel with gentle pressure in the direction shown by the drawing.

Then, guide the blade alon the whole length of the opposite side of the steel. Repeat the process several times to maintain the same angle of 20° to 30°.

The "razor sharp"

The length of time an edge lasts depends on two processes: the tempering/hardening and the grinding (the application of the fine edge). The tempering is the thermal treatment of the steel. This gives it the qualities of elasticity and durability. The grinding involves folding together a rectangular section of the steel with a perfectly triangular section. The more precise the measurements, the easier the blade is to sharpen. At this stage, a delicate balance is sought between a cutting edge that is strong but too thick to cut properly. If an edge cuts well, it is too fine and is fragile. A fragile edge will snap or corrugate with cutting hard material like bone. A good example is a shaving razor - it is great for the delicate operation of shaving but you would never use it to carve a roast! Nor, would you attempt to shave with a carving knife. A new knife of good quality is often sharp enough to shave but it will not keep this almost-perfect cutting edge unless sharpened VERY often!